About Discrimination

Our efforts

(before the identification)

At Kishun, Akoya pearl necklaces purchased from our customers are inspected by our in-house professional staff, We also carefully polish each pearl to restore the original luster of the pearl.

We also polish each pearl carefully to restore the original luster of the pearl. “

Visual inspection.

Place the pearl on a white cloth and observe the entire surface of the pearl while rotating it.

The Master pearl Aurora Viewer is used to check for color and brightness.

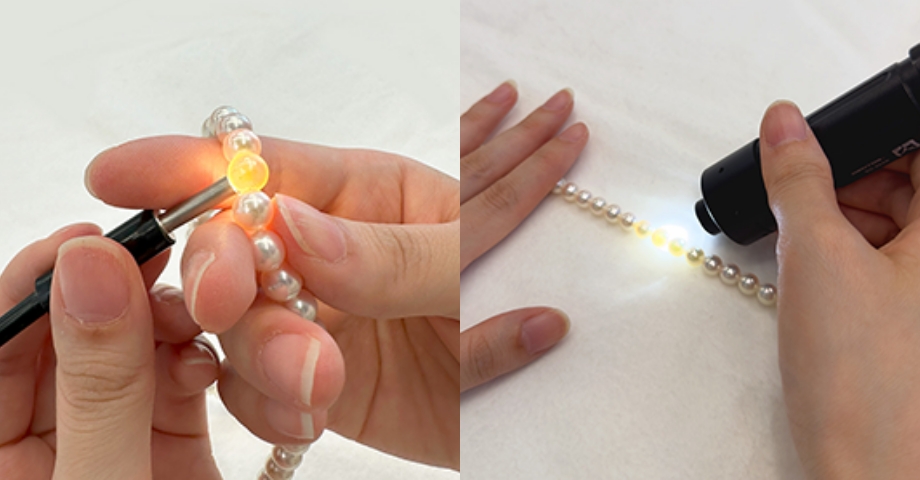

Optical transparency inspection

The surface and interior of the pearl is inspected by shining a strong light on it.

The size of the nucleus and the absence of cracks are checked.

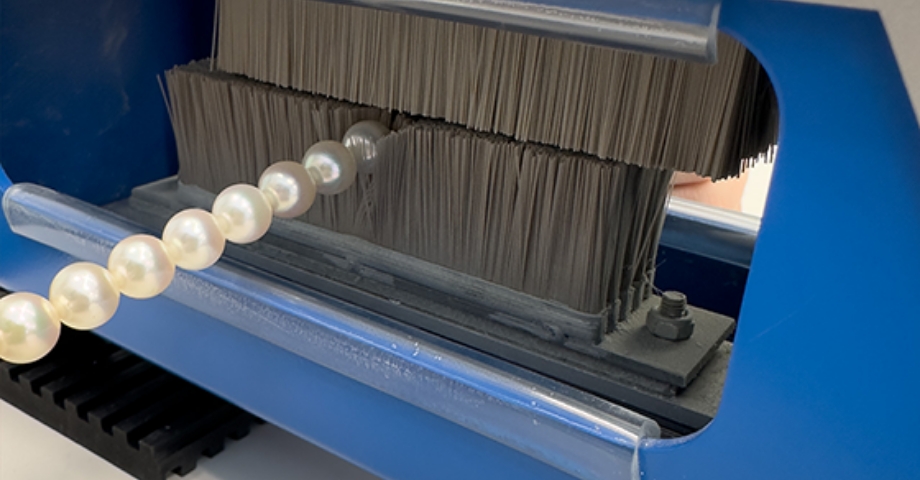

Polishing.

Use a pearl refresher to clean areas that cannot be wiped off with a cloth.

About RSE's quality inspection and grading system

The key to pearl quality is beauty and durability.

In pearls, luster means luster with interference color, and it is said that the beauty of a pearl is determined by its luster.

Nacre coating is the thickness of the nacreous layer, which is formed by thousands of thin layers wrapped around the nucleus at the center of the pearl.

Luster and nacre coating are closely related in terms of the beauty of Akoya pearls.

The denser the nacreous layer structure, the stronger the luster, and pearls with thicker nacre coating are more durable and can be used for a long time beyond generations.

Kishun Pearl, in collaboration with RSE Laboratory, one of the leading pearl identification laboratories in Japan, has established a new value standard that emphasizes luster and nacre coating.

Quality Inspection Flow

Identification as genuine pearls → Quality inspection → Pass → Grading

The durability of the pearl as a gemstone is inspected for four quality items: luster, nacre thickness, surface condition, and maching (necklace only), and a pearl is considered to have passed the RSE pearl quality inspection if it meets the requirements for a gemstone.

Quality Inspection and Acceptance Criteria

| Quality Items | Conditions for passage | |

|---|---|---|

| Quality Items | Visual inspection shall show that the pearlescent luster is equal to or greater than Fair (weak) in the five levels of luster master pearls. | |

| Nacre thickness | In the case of nucleated cultured pearls, the internal stripes of the nucleus shall not be clearly visible through a light transmission test using a fiber optic light source, or the thickness of the nucleus shall be such that it is difficult to see the stripes. | |

| Surface | Nacre | "There shall be no exposed ridge column layer or organic layer on the surface, and the entire surface shall be covered with a nacreous layer. No critical damage shall be present upon visual inspection. No layer cracks or exposed cross sections due to surface cuts or carvings. There shall be no traces of lamination on the surface." |

| "Machining Defect" | Processing flaws can cause quality deterioration, so there should be no damage to the surface such as cloudiness, spots, cracks, or significant skin irritation due to processing. Dyed treated pearls should have no dye residue on the surface that causes problems when worn. |

|

| Damage | No nucleus exposed due to delamination or chipping of the nacreous layer. No noticeable protrusions that pose a high risk of breakage. The nacreous layer shall not be broken visually or by light transmission inspection. |

|

| Matching | For a necklace or a series of necklaces, a grade of Fair (slightly discordant) up to 5 is acceptable. For baroque and multi-colored pieces, the overall harmony is considered acceptable. |

|

Pearls that have passed all of the above quality requirements for currency are considered to have passed the RSE Pearl Quality Inspection.

Grading System

| Quality Items/Categories | Excellent | Very Good | Good | Fair | Poor |

|---|---|---|---|---|---|

| Luster | Excellent | Very Good | Good | Fair | Poor |

| Nacre thickness | Thick | Slightly Thick | Medium | Thin | VeryThin |

| Surface (Surface smoothness and scratches) |

Clean | Lightly Spotted | Moderately Spotted | Heavily Spotted | Fatal Spotted |

| Matching | Excellent | Very Good | Good | Fair | Poor |

・Notes

Jewelry consisting of multiple pearls, such as necklaces, are graded based on the overall quality of the product as a whole.

For a set of multiple items, the grading of the set as a whole is indicated.

・Indication of nacre thickness

Nacre thickness is described in 0.05mm increments, rounding down to the third decimal place. Example: Approx. 0.45mm

Evaluation of Luster and Pearl Coating

We have created a new standard of value for pearls by placing emphasis on the evaluation of “Luster,” which is the beauty of appearance, and “Nacre thickness” which emphasizes durability, both of which are important as jewelry.

About Luster Evaluation

We visually evaluate the teri under constant illumination in comparison with the master pearl, and we have a double-checking system to ensure that there are no discrepancies in the evaluations.

About the Evaluation of Nacre thickness

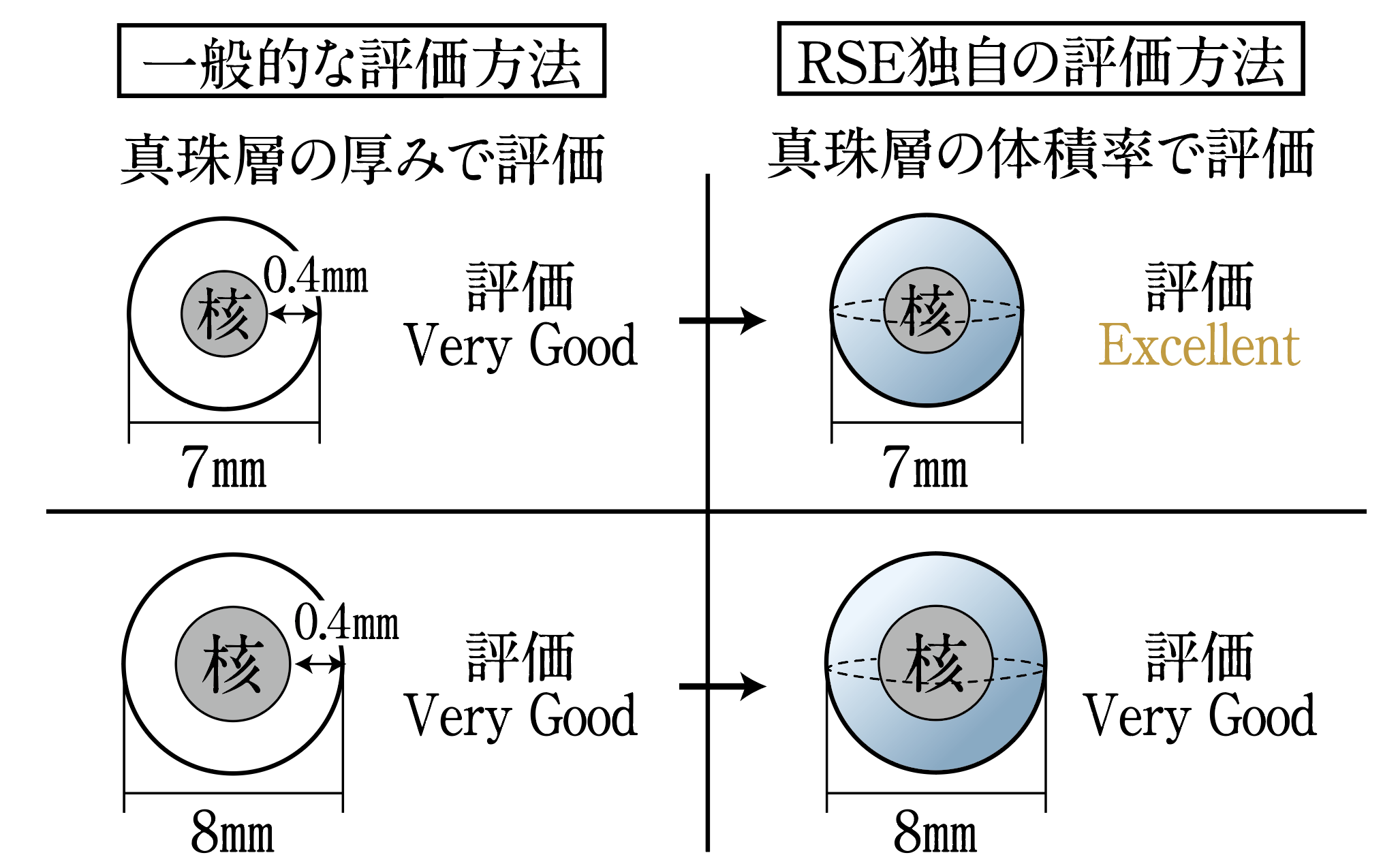

Generally, the coating grade is measured by the thickness of one side of the nacreous layer, and simply the thicker the roll, the higher the grade, but this does not take into account the diameter of the pearl in relation to the size of the nucleus.

RSE has studied how much of the nacreous layer formed on top of the nucleus occupies the entire nacreous layer, and has established a standard for the volume percentage of the nacreous layer for each pearl diameter.

In other words, when comparing two pearls of 7 mm and 8 mm diameter with the same winding thickness, if the nucleus of the 7 mm diameter pearl has a smaller diameter, the volume fraction of the nacreous layer will be higher than that of the 8 mm diameter pearl, which means that the coating is rated higher.

*The results of the RSE study were presented at the Gemological Institute of Japan in June 2022.